SWINBORNE’S ISINGLASS FACTORY

Isinglass

Strange and unlikely as it may seem the raw material for the manufacture of isinglass is the swim bladders of certain species of fish. The fish use them to control their buoyancy at different depths but it is thought that their usefulness to us may have been discovered by Mediterranean fishermen. They used them to store wine and discovered that cloudy wine emerged from the bladder crystal clear, the ‘cloudiness’ had fallen to the bottom to form a layer from which the clear wine was easily decanted.

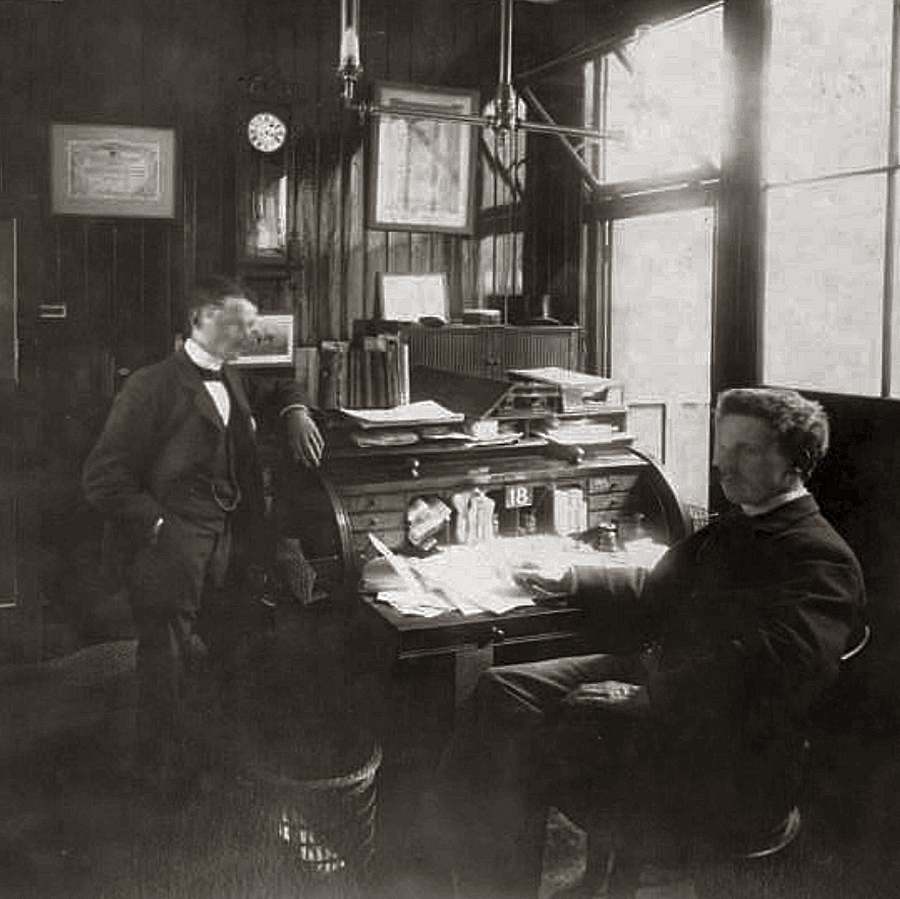

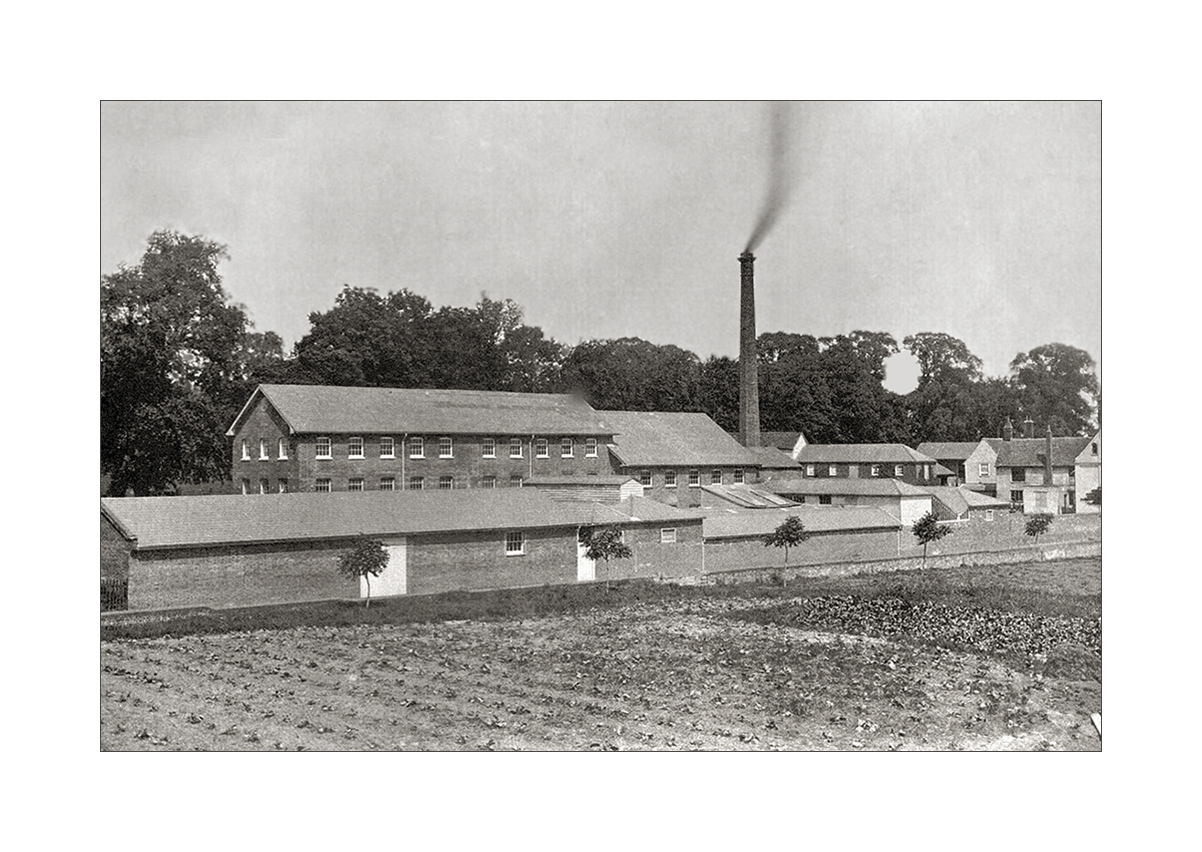

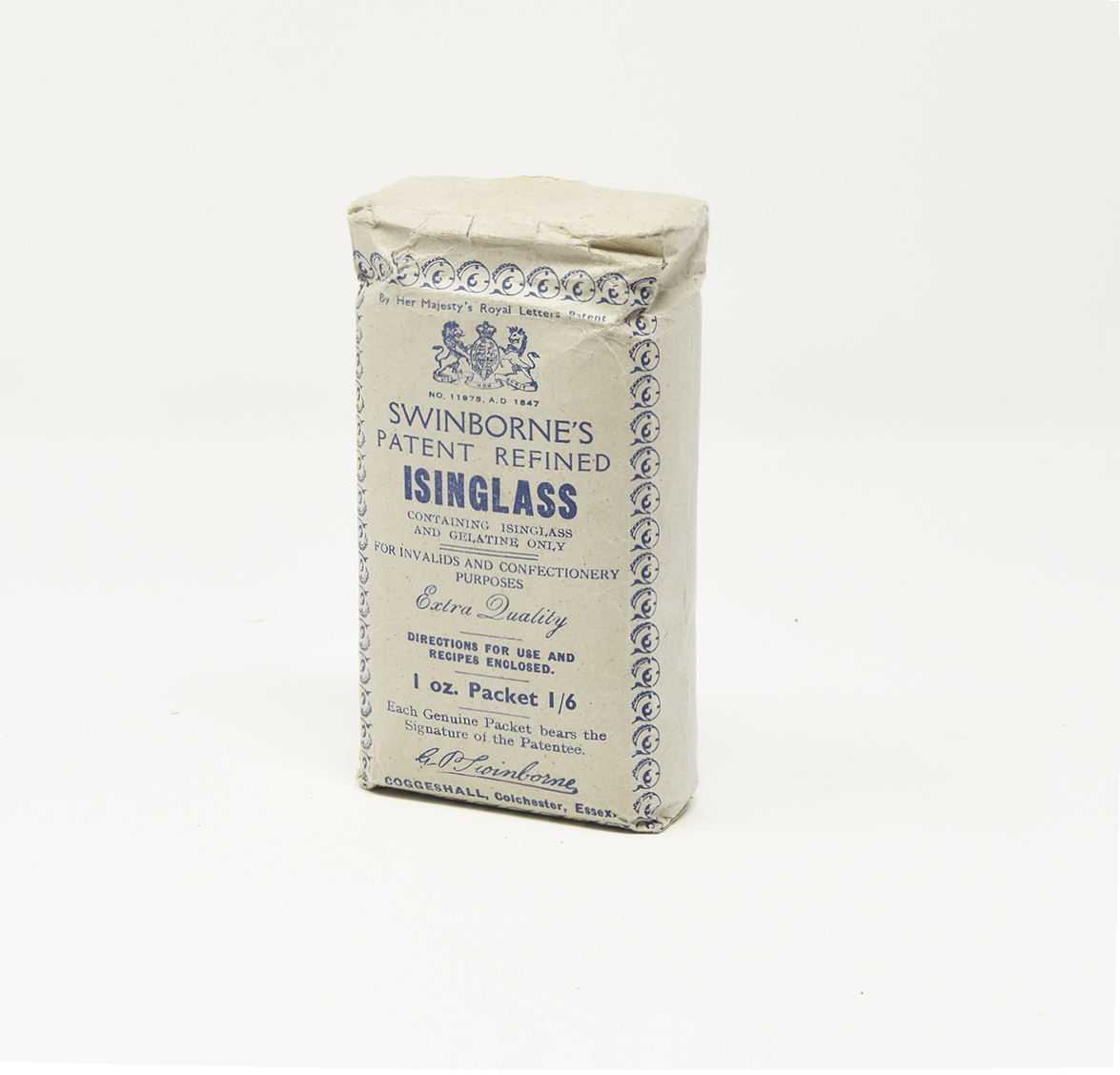

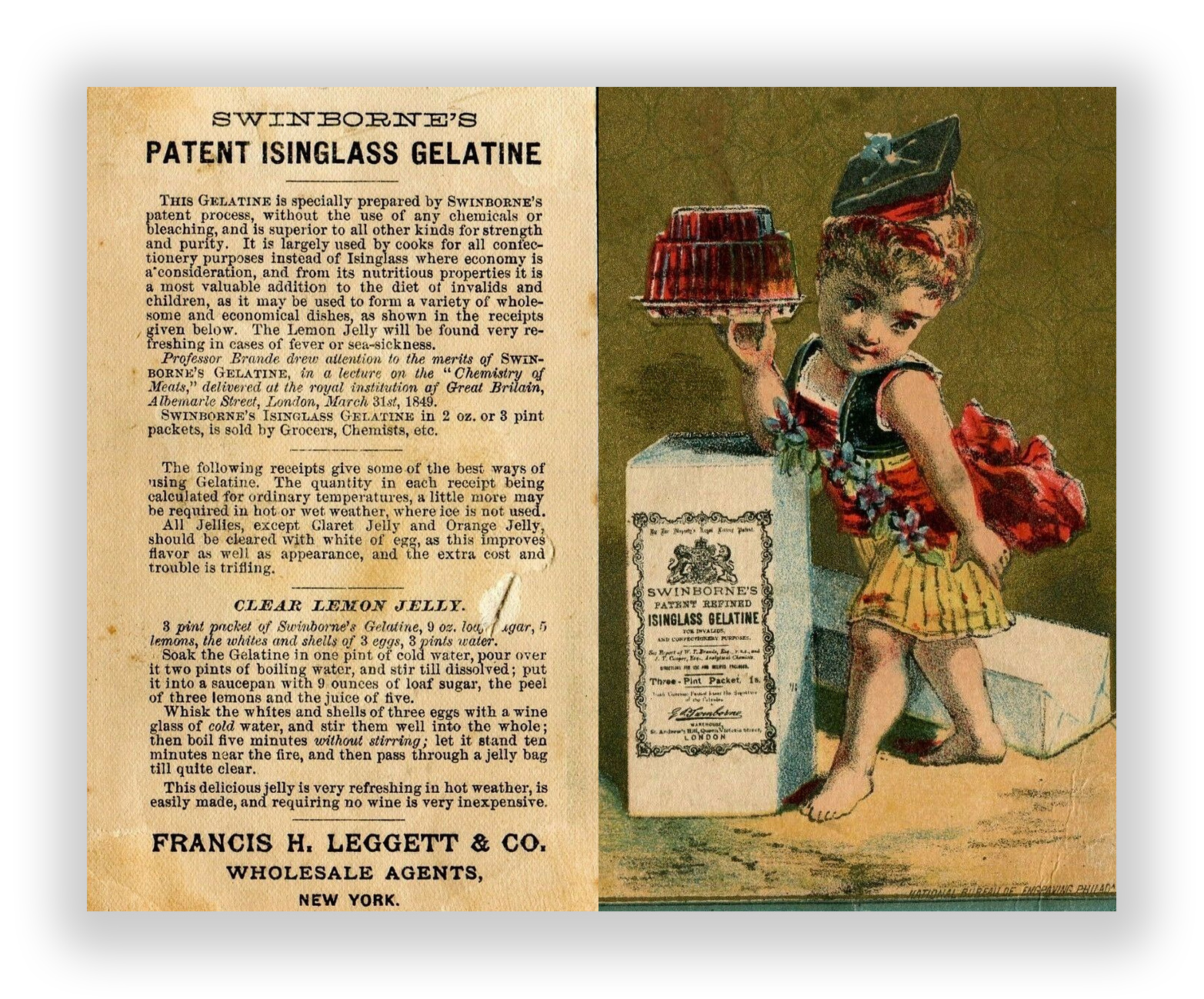

Originally Swinbornes were tanners and curriers (leather workers) operating from premises in East Street and at the far end of West Street – where the smelly business of tanning most like took place, well away from the centre of town. As well as leather, animal glues were also made, derived from the rendered skins of animals. These glues can be produced in a range of qualities of which the most refined is Gelatine. In 1847 George Swinborne was granted a patent for an improved method of manufacturing it; ‘Improvements in the Manufacture of Gelatinous Substances and in the Apparatus to be Used Therein’. The pure form of gelatine which resulted from this process he called ‘Patent Isinglass‘. This is transparent and has no taste or smell and uses no chemicals in its manufacture. Production was started in part of premises formerly used by the tannery but these were soon extended as demand grew.

Between 1850s and the 1870s there was a huge expansion in the business, and ‘as Thomas Swinborne & Co, Patent Isinglass and Gelatine Refiners and Manufacturers’ more buildings were put up and when the tannery closed in the 1870s its premises were also taken over. Isinglass was widely sold to make jellies and as an ingredient in other domestic foods but it was the production of isinglass for use as ‘finings’ to clarify beer and wine which was responsible for the success of the business. Swinborne’s finings were used in the brewery business throughout the UK and enjoyed a considerable export market especially to the USA.

The dried fish bladders – called ‘Maws’ were at first imported from the Mediterranean but later supplies came from South America and from various species of fish, such as Brazilian Lump, South American Purse and Pipe fish. After the bales of maws were opened, inspected and graded they were washed and bleached and rolled several times to form a long strip. After the lengthy drying process the isinglass was finished in various ways according to the market; from small transparent sheets or powder for the domestic market or for industrial use it was formed into folded sheets, cut into strips, shredded or sold as a liquid.

Html Mid Grey background ignore this text it is just to increase the picture size

ignore this text it is just to increase the picture size

ignore this text it is just to increase the picture size

ignore this text it is just to increase the picture size

ignore this text it is just to increase the picture size

By 1875 the business was known as ‘G P Swinborne & Co, Isinglass and Gelatine Manufacturers’ and expansion continued to the end of the 19th century. The Swinborne family sold the factory in 1930 and it came under the ownership of the ‘Isinglass Manufacturing Co’.

The last owners, James Vickers Ltd, closed the works in the 1999 with the loss of around ten jobs. It had been decided that isinglass production should be concentrated in the brewery town of Burton-on-Trent. The old factory buildings in Coggeshall were later converted into flats.

The main tannery building at the Isinglass factory is now Listed Grade II.

Here is a link to the Historic England Listing description. Isinglass Factory Listing Details